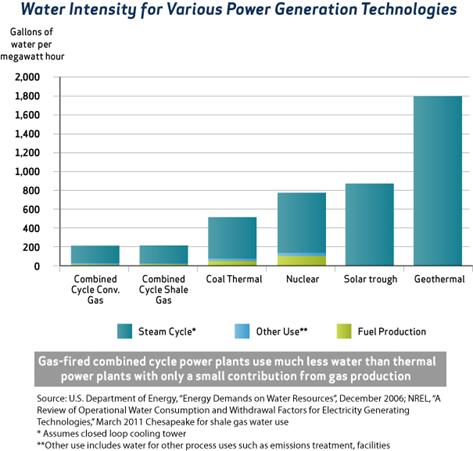

Hydraulic fracturing, commonly referred to as fracking, is a method used to extract natural gas from shale gas deposits. Natural gas is advantageous because it is much less water intensive than most electrical power technologies (see figure 1). This includes water required for production. Additionally, electricity produced from natural gas emits half as much greenhouse gas as coal power [5]. Considering that 44 percent of the world’s power comes from coal, a transition to natural gas would help developed nations come closer to meeting their carbon budgets [5]. In fact, the US electricity sector has reduced its CO2 emissions to their lowest level since 1994 because of this shift from coal to natural gas [14]. Currently 24 percent of the world’s energy consumption comes from natural gas [16] and between 60 and 80 percent of that comes from fracking [17]. The rest of natural gas production comes from conventionally drilled wells [16].

Figure 1: Volumes of water used per unit of power for different types of electricity production [1]

While it is unlikely that the world will quickly shift to renewable sources of energy, a transition from coal to natural gas produced by hydraulic fracturing would put the world on a path towards energy sustainability. This fact along with projections from the US Energy Information Administration [16] suggests that natural gas will take a leading role in world energy consumption in the near future. This will present a serious hazard to the future of water security if current practices aren’t changed. Fracking, as currently practiced, can be hazardous to both the environment and human health. The purpose of this article is to identify these problems and present solutions that would allow natural gas to become a realistic and safe energy source for the near future.

Terminology

While this article focuses mainly on natural gas deposits in shale rock, hydraulic fracturing is technically a method of increasing the recovery rate of any type of well, including natural gas, oil, even water wells. It is not even a new development. Fracking was first applied by oil producers in the US as early as 1949 [4]. However, it was not until recently that fracking was used to acquire shale gas on a large scale, and, though hydraulic fracturing has a very broad definition, it is most commonly used for stimulating gas wells and will be used in this article specifically to describe fracking for shale gas.

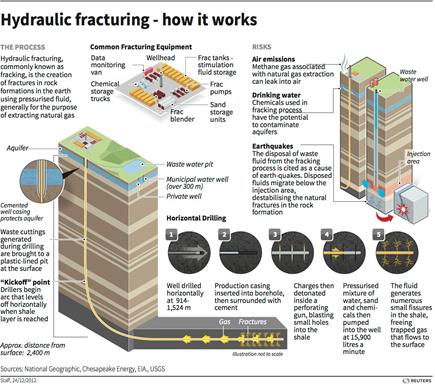

Fracking Method

In order to free natural gas from shale deposits high volumes of high pressure fluids are injected into natural gas wells deep underground (see figure 2). These fluids are composed of 90 percent water, 9.5 percent sand, and 0.5 percent other chemical additives such as ethylene glycol, borate salts, and hydrochloric acid [4]. Most of these additives are used to prevent corrosion of the metal pipes and to maintain the viscosity of the fluid [4]. When the fracking fluid is injected into the well it creates small fissures in the rock layer containing the natural gas. The sand grains in the fluid keep these fissures open while the rest of the fluid is removed from the well. This frees the natural gas, allowing it to flow freely into the well to be harvested [4].

Figure 2: The typical fracking method [2]

The well itself is a steel pipe inserted into a drilled borehole, which is then cemented into place. The intention of this is to prevent natural gas and fracking fluid from leaking into groundwater, however if this casing becomes compromised then there is a high probability that the groundwater will be polluted [7].

Problems

The biggest concerns with fracking are environmental and health concerns. For example, in the United States fracking doesn’t fall under the regulation of the Clean Air and Water Act [5]. Additionally China, with almost 1.5 times the shale reserves of the US, doesn’t have any substantial environmental regulation [19]. This allows natural gas companies to operate without disclosing the chemicals they are injecting into the ground. If there is a report of contaminated ground water near a fracking site, this nondisclosure makes it very difficult to actually link the contamination to fracking [7].

Hydraulic fracturing produces enormous volumes of wastewater, which are typically either injected back into the ground or processed by wastewater treatment plants [5]. Unfortunately, these treatment plants are often overwhelmed by the sheer volume of wastewater produced during fracking, and there have been reported incidences in the Marcellus basin of wastewater plants dumping contaminated water into local rivers and streams [13].

Additionally, many natural gas deposits are located in water stressed areas, for example the Karoo Basin in South Africa or the Turpan Basin in China. Because hydraulic fracturing requires large quantities of water, any shale gas development in already water stressed areas will create a conflict between gas companies and local farmers.

Environmental Regulation

One way to hold natural gas companies responsible for any damage they do to the environment (specifically the water table) is to require them to disclose any chemicals put into gas wells. In the United States this could come in the form of the FRAC Act, which as of November 2013 is still being debated in Congress [15].

Figure 3: A natural gas well in Pennsylvania [3]

In addition to requiring natural gas companies to disclose the chemical additives used for fracking, they must also be required to follow Best Management Practices for storm water management and surface spills. One of the most commonly cited violations by the Pennsylvania Department of Environmental Protection is silt and debris runoff during storms [12]. This is an entirely preventable violation, and should be more heavily regulated. One good example that other countries could work off of is South Africa’s Mineral and Petroleum Resources Development Act (MPRDA) [18].

When fracking fluid is withdrawn from natural gas wells it is usually stored in lined open pits or metal tanks [12]. This contains clays, salts, and minerals broken loose from the rock, in addition to the water, sand, and chemicals initially put into the well. These fluids and gasoline from vehicles and other equipment can spill into the surrounding environment. While there haven’t been any “substantial” cases of spills like this entering the groundwater it is certainly still a possibility and an environmental concern [12]. This is completely preventable with environmental regulation and appropriate punishment for violations.

Additionally, environmental regulation should cover methane leakage both during production and transportation of the natural gas. This is important because methane is a very powerful greenhouse gas; as much as 20 times as potent as carbon dioxide [9]. A recent study found that “green completions” technology used at natural gas wells capture 99 percent of potential methane emissions, however they found that pneumatic switches, used to control equipment at well sites, leaked more than expected [9]. These should be regulated to further reduce methane emissions.

Improved Wastewater Treatment

Wastewater treatment plants undergoing chlorination treatment release some unwanted byproducts called chlorinated trihalomethanes [13]. If wastewater from hydraulic fracturing is processed by these plants other harmful byproducts called brominated trihalomethanes are produced, increasing the concentration by weight of total trihalomethanes. One way to get around this problem is to require that treatment plants limit their chloride content in surface water discharge to 250 mg/L chloride, which newer treatment plants are capable of doing. This method has been proven successful in Pennsylvania [13].

Fracking Fluid Alternatives

While water is the most commonly used fracking fluid, and as of now the most economically advantageous, it is not the only type of fluid that can be used. It is also possible to use liquid propane, saltwater, and high pressure CO2 to extract natural gas [6]. While this isn’t practical in areas with plentiful freshwater reserves, places like the Turpan Basin in China and the Karoo Basin in South Africa are extremely water stressed and would benefit from alternatives, and it would be both more economically and environmentally feasible for them to rely on alternatives.

High pressure CO2 is a particularly attractive alternative, because it has the added advantage of reducing (if only by a small amount) carbon emissions from burning fossil fuels [6]. Also, fracking with carbon dioxide eliminates the wastewater produced in the conventional fracking process. This method is currently being practiced in Wyoming, where carbon dioxide pipelines already exist [6].

Corrosion Resistance

Most of the chemicals added to the fracturing fluid are either meant to help initiate cracks in the shale or to prevent corrosion of the steel pipes carrying the fluid into and out of the ground [4]. These chemicals preventing corrosion would not be necessary if natural gas companies utilized corrosion resistant pipes and storage tanks. For example, fiberglass Reinforced Plastics (FRPs) are corrosion resistant and are capable of withstanding harsh environments that might be present in fracking [11].

Water Recycling

After a natural gas company has finished fracking a well they typically pay for the flow-back fluid to be sent off and treated in a local wastewater treatment plant which, as mentioned previously, can be very overwhelming for the treatment plants. Additionally, this is wasteful and can be costly for the company. To solve this problem, the flow-back fluid can be recycled on site to be used another time [8]. This has the benefit of cutting the cost of disposal and of obtaining fluids needed for new fracking jobs, as well as improving the company’s public image. Also, this water could be treated and used to in new combined cycle power plants, which create power with both gas and steam turbines. This process has a gas turbine generating electricity as well as a steam turbine using the waste heat from the gas turbine to generate additional electricity. This innovative process is extremely efficient; generating more power than either process could in isolation [10].

Implementation

The first and most critical solution to be implemented is environmental regulation, which should take place as soon as possible in countries that currently produce natural gas from fracking, and should be implemented prior to development of hydraulic fracturing in countries that are considering developing their shale gas resources. It is in the governments’ best interests because unregulated fracking poses a risk to both the environment and human health. The next solutions to be implemented, probably in the next 5 to 10 years, are best management practices such as water recycling and reduced chlorination in treatment plants processing fracking wastewater. Finally, solutions to be implemented over the whole lifetime of fracking are the technically innovative solutions, such as corrosion resistant equipment and fracking fluid alternatives. If these solutions are implemented, hydraulic fracturing will be a safe, reliable, and water friendly source of energy providing the world a path to transition from coal and petroleum power to cleaner, more sustainable sources.

References

1. (December 2006). Water Intensity for Various Power Generation Technologies. Conoco Phillips. Retrieved from http://www.powerincooperation.com/EN/Pages/water.html

2. Richman, Josh. (August 28, 2013). Fracking battle heats up for session’s final weeks. Political Blotter. Retrieved from http://www.ibabuzz.com/politics/2013/08/28/fracking-battle-heats-up-for-sessions-final-weeks/

3. (October 17, 2012). Top 20 Health Concerns Related to Fracking. Neogap. Retrieved from http://www.neogap.org/neogap/2012/10/18/top-20-health-concerns-related-to-fracking/

4. (July 19, 2010). Hydraulic Fracturing: Unlocking America’s Natural Gas Resources. American Petroleum Institute. Retrieved from http://www.api.org/policy/exploration/hydraulicfracturing/upload/HYDRAULIC_FRACTURING_PRIMER.pdf

5. (April 2009). Modern Shale Gas. US Department of Energy. Retrieved from http://www.netl.doe.gov/technologies/oil-gas/publications/EPreports/Shale_Gas_Primer_2009.pdf

6. Bullis, Kevin. (March 22, 2013). Skipping the Water in Fracking. MIT Technology Review. Retrieved from http://www.technologyreview.com/news/512656/skipping-the-water-in-fracking

7. Mall, Amy. (June 17, 2013). Incidents where hydraulic fracturing is a suspected cause of drinking water contamination. Natural Resources Defense Council. Retrieved from http://switchboard.nrdc.org/blogs/amall/incidents_where_hydraulic_frac.html

8. Caruso, David B. (January 3, 2011). 44,000 Barrels of Tainted Water Dumped Into Neshaminy Creek. NBC Philadelphia. Retrieved from http://www.nbcphiladelphia.com/news/local/Pennsylvania-Allows-Fracking-Tainted-Water-Dumping-Gas-Drilling-112804034.html

9. (September 17, 2013). Study: Less methane leaks from fracking than EPA says. Science News. Retrieved from http://www.upi.com/Science_News/2013/09/17/Study-Less-methane-leaks-from-fracking-than-EPA-says/UPI-90201379399400/

10. Inner Workings of a combined cycle power plant. General Electric. Retrieved from http://www.ge-flexibility.com/power-generation-basics/how-combined-cycle-works/index.html

11. Mettry, Matthew. (July 1, 2013). FRP Applications for common fracking chemicals. Beetle Plastics. Retrieved from http://www.beetleplastics.com/blog/bid/300237/FRP-Applications-for-Common-Fracking-Chemicals

12. Brzycki, Elaine. Explore Shale. PennState Public Broadcasting. Retrieved from http://exploreshale.org/

13. (March 2012). Fracking: the new global water crisis. Food and Water Watch. Retrieved from http://documents.foodandwaterwatch.org/doc/FrackingCrisisUS.pdf

14. Walsh, Bryan. (October 22, 2013). Bye-Bye, Carbon: The US is (slowly) winning the emissions war. Time US. Retrieved from http://nation.time.com/2013/10/22/efficiency-natural-gas-keep-pushing-u-s-carbon-emissions-down/

15. Casey, Robert. (June 11, 2013). FRAC Act. United States Senate. Retrieved from https://www.govtrack.us/congress/bills/113/s1135

16. (September 28, 2011). Renewable energy shows strongest growth in global electricity generating capacity. US Energy Information Administration. Retrieved from http://www.eia.gov/todayinenergy/detail.cfm?id=3270#

17. Svoboda, Elizabeth. (December 13, 2010). The Hard Facts About Fracking. Popular Mechanics. Retrieved from http://www.popularmechanics.com/science/energy/coal-oil-gas/the-hard-facts-about-fracking

18. van Vuuren, Andre J. (September 11, 2012). SA gives cautious ‘yes’ to shale gas. Mining MX. Retrieved from http://www.miningmx.com/page/news/energy/1391534-SA-gives-cautious-yes-to-shale-gas

19. Watts, Jonathan. (April 21, 2011). China takes step towards tapping shale gas potential with first well. The Guardian. Retrieved from http://www.theguardian.com/environment/2011/apr/21/china-shale-gas-well